Nolan's Going The Distance

Jan. 27, 2017

For some Traverse City companies, sourcing the best product possible means looking no further than their own backyards. For others, quality control could mean a 2,200-mile flight.

Nolan’s Tobacco and Cigar Bar Owner Mike Nolan has sold imported cigars from around the world at his shop at 336 East Front Street since 1978. As consumer demand shifted over the decades away from pipes and pipe tobacco and toward cigars, Nolan’s business model also flip-flopped.

“We now sell a lot of cigars and few pipes,” says Nolan. “That changed as consumers changed, and there is a plethora of market reasons for that.” Today, the average Nolan’s customer smokes a cigar two to three times a week, according to the owner, though a wider demographic stops by once or twice a year. “It’s a celebratory thing when someone wins an award or there’s the birth of a child or the closing of a business deal,” says Nolan.

The uptick in demand for imported cigars in recent years has required Nolan’s to broker relationships with numerous cigar manufacturers, who grow the tobacco in tax-free zones – primarily in Central America – then import the cigars through stateside offices. From there, Nolan’s has a state license that allows the store to buy the cigars directly from the manufacturers and sell them to customers.

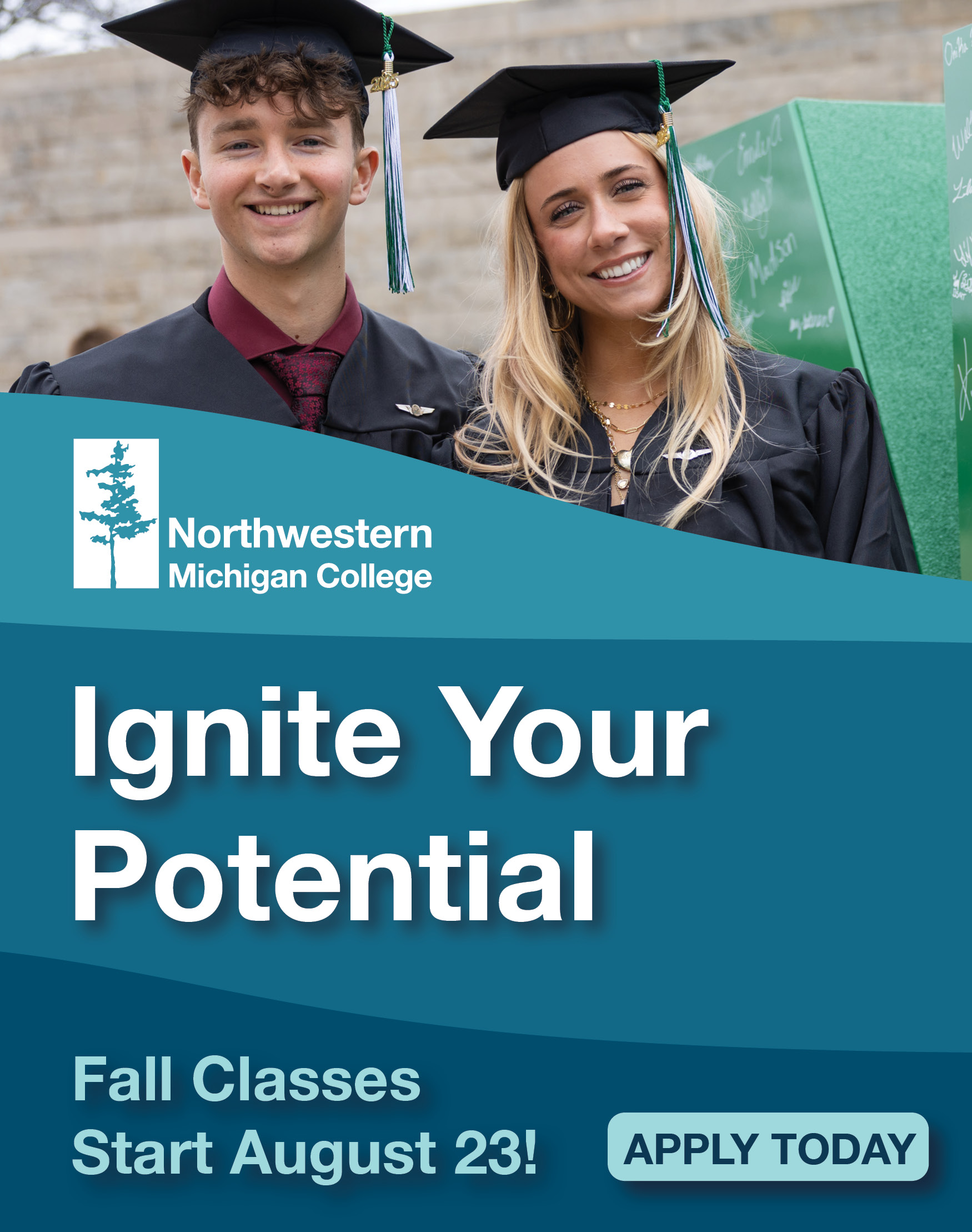

The vast majority of Nolan’s top-selling cigar brands hail from either Nicaragua or the Dominican Republic. To witness firsthand how the products are made – and to better answer customers’ detailed questions about each cigar’s origins – Nolan’s Co-General Managers Andy Hyde and Ben Wyckoff recently traveled to Esteli, Nicaragua, to spend several days touring the Perdomo Factory.

“We learned far more than we expected to,” says Hyde. “We saw every part of the process of making a handmade cigar.” Wyckoff says the duo were able to observe the intricacies of the estimated 3,000 steps that go into producing a premium cigar, “starting at the seeds and sorting those, then (planting them in) the fields, then the long curing process” – all complex stages followed by fermenting and stripping the tobacco leaves and hand-rolling the cigars, he says.

Nolan, who has himself traveled to the Dominican Republican to tour tobacco operations in that country, notes it takes “400 people to touch each handmade cigar before it comes to market. The average production time is four years.”

Cigar factories are also big business in these countries: The largest plants can employ between 4,000 and 6,000 people. “Being a cigar roller is a skilled premium position,” says Nolan. “(The employees) get paid way above average wages.”

Touring the Nicaraguan factory and observing the plant’s cigar-making operations has helped the staff better sell cigars back here in Traverse City, according to Hyde and Wyckoff. “We like to give a fair amount of information to our consumers, because they want to know a lot about the process,” says Wyckoff. “Watching that particular blend be made helps on a sales point. Andy and I have both been in the business for 13 years, and taking this trip really showed me there was and is still a lot to learn.”

While Nicaraguan and Dominican Republican cigars remain the most popular – with Nolan’s staff now having visited operations in both countries – another country still remains a hot topic of conversation among customers: Cuba.

“The question we get on a regular basis is, ‘Can we buy Cuban cigars here (at the store) now?’” says Nolan. “The answer is no.”

While former President Obama recently lifted restrictions between the U.S. and the Cuba, the newly relaxed rules only allow American tourists to bring up to 100 cigars back into the country from Cuba, or to purchase Cuban cigars in other countries where they are legal. A federal embargo remains in place, however, on commercial entities like Nolan’s buying Cuban cigars for resale in America.

Even if that embargo is eventually lifted – which would require a vote of the Republican-controlled Congress – Cuba’s government-run cigar industry would have to contend with the scores of companies who fled the country and claimed trademarks on Cuban product names here in the U.S.

“When the (embargo) law gets changed, there are still trademark issues that are going to be in the courts for a long time,” says Nolan. “You’re not going to see legal Cuban cigars sold in this country for probably 20 years.”

Pictured: Andy Hyde and Ben Wyckoff (left and right) touring the Perdomo operations in Nicaragua.